- Description

As an advanced high-performance servomotor, Ultract HX series AC permanent magnet synchronous servomotor can satisfy the extensive need of industrial automation and process control, especially suitable for the application scenarios of direct drive.

ROTOR

The stamped steel uses silicon steel sheet of high performance and low loss, carrying out the simulating analysis of mechanical strength through finite element method;

Minimize the inertia of rotor with premise of enough mechanical stiffness and mechanical strength;

The rotor magnet uses NdFeB permanent magnet material of high performance to form sine wave air-gap field;

The shaft uses bond burying processing method, and meet the requirements of optical axis and bond axis at the same time.

STATOR

The stamped steel uses silicon steel sheet of high performance and low loss;

The level of magnet wire insulation is C while the level of integral insulation is F;

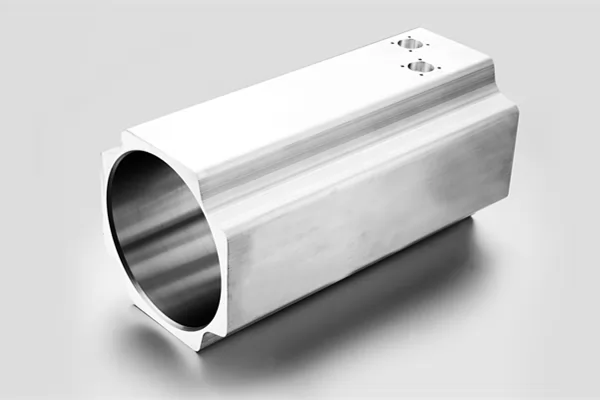

The shell uses high-strength aluminum shell, and the shell and air shaft are optimized through finite element temperature field analysis, with large temperature gradient and good heat dissipation effect.

ASSSEMBLY

Reasonable structure, and high-power density; Very small rotor inertia, and very fast response;

Rare earth permanent magnetic material of ultra-high intrinsic coercive force and strong anti-demagnetization capability;

Constant torque output within locked-rotor and rated speed range;

Special asymmetric design of magnetic circuit makes the pulsation small of torque at low speed;

High balance quality, high speed smooth operation, low noise, and small vibration;

Omniseal and high protection class contour structure design.

Ultract HX series AC permanent magnet synchronous servomotor has high torque/ volume ratio and power/volume ratio and is equipped with optical or inductive encoder. As a standard feedback device of servomotor, this encoder can provide the absolute position encoding of 8 million points per turn. Therefore, it has the best stability with extremely low speed of servomotor. Or you can choose multi-ring absolute encoder with Endat interface and electronic nameplate. Based on above characteristics, it can overcome the limitations of mechanical driving device and make numerous application scenarios completely adopt direct drive technology.

There are 6 Ultract HX series AC permanent magnet synchronous servomotor from the smallest No.3 base to the largest No.18 base, a total of six series. The pull-in torque of No.3 base servomotor is 2NM, suitable for chassis with the flange dimension of 75mm, used for minimal localization and the installation of small parts, and able to replace DC and stepping motor; the large servomotor of No.13 base, with the power of 200KW and the maximum torque of 700NM, suitable for direct and distributed driving on the continuous production line, so as to overcome the continuous power consumption of long distance transmission link. The standards are 220/240Vac or 380/460Vac. The input voltage of No.10 and No.13 base servomotor is 380/440Vac. At the same time, there are the choices of natural cooling, forced air cooling and water cooling. With the features of low rotational inertia, high accuracy and fast response, etc, suitable for direct and distributed driving on the continuous production line, so as to overcome the continuous power consumption of long distance transmission link.