Introduction of Annealing Technology in Aluminum Profile Processing

Date:2022-08-17

Introduction of Annealing Technology in Aluminum Profile Processing

Aluminum profile processing annealing is divided into strip annealing and foil annealing. The purpose of annealing: eliminate cold work hardening for continued rolling or deep processing; control the state and performance of the product; remove rolling oil and improve surface quality.

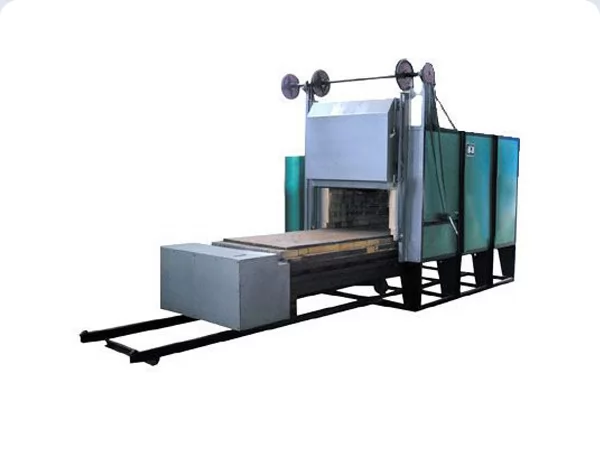

According to production capacity and scale, aluminum annealing furnaces are divided into annealing production lines consisting of single annealing and annealing furnace groups. bypass cooler). The furnace body adopts a large air volume fan to circulate and heat the aluminum material. The diversion device in the furnace can effectively ensure that the air flow evenly passes through the aluminum material, so that it can be heated evenly. The heater adopts a top-mounted integral structure, which is very convenient for disassembly and maintenance. The opening and closing of the furnace door adopts pneumatic pressing type or mechanical transmission lifting type, which has stable operation and good sealing performance. The fume extraction system of the furnace can effectively remove the oil film on the surface of the aluminum material and adjust the pressure in the furnace. The charging capacity of this kind of furnace is generally 10-50t.

The aluminum annealing furnace is the most widely used equipment in the processing and heat treatment of aluminum profiles. With the development of technology and the improvement of product quality requirements, higher requirements are put forward for the annealing of aluminum materials, such as the appearance quality of annealed products and the consistency of performance indicators. The appearance quality includes peeling, bubbles, oil spots, oxidation corrosion, surface finish, etc. Intrinsic quality includes mechanical properties, grain size, anisotropy and so on. In addition to the annealing process and equipment, the processing history of the product before annealing, such as ingredient composition, casting process, cold working rate, etc., also has an important impact on the intrinsic quality of the annealed product.

In order to improve the quality of annealed products, it is necessary to take improvement measures in furnace atmosphere, furnace temperature control, furnace type and so on.

①For annealed products with special requirements, a protective gas with very little oxygen and moisture content can be used as the atmosphere of the annealing furnace to prevent the cracking of rolling oil molecules during the volatilization process, resulting in hydrocarbons and free tiny carbon particles. Oil spots are generated on the surface of the product; at the same time, the thickness of the oxide film on the surface can be reduced, so that the original metallic luster can be basically protected after the product is annealed.

When using protective gas, first heat the furnace to about 150 ℃, after charging, fill the furnace with protective gas to wash the furnace, and then heat up. During the heating period, the oil film on the surface of the product volatilizes and is discharged from the exhaust port, and at the same time, the protective gas is supplemented to maintain the positive pressure of the furnace. After the oil film is completely volatilized, high temperature heating and heat preservation are performed to recrystallize the product in a relatively short time, and then the temperature is lowered and released.

②Vacuum annealing is a relatively new aluminum profile processing annealing technology, which can prevent the cracking, oxidation and polymerization of rolling oil molecules. During vacuum annealing, the furnace is first pumped to a certain degree of vacuum, and then heated. During the heating process, it needs to be filled with A small amount of protective gas is used to remove oil and gas, reduce the load on the vacuum pump, and accelerate the convective transfer of heat. At the beginning of cooling, it is necessary to charge more protective gas than normal operation to maintain a slight negative or positive pressure in the furnace, and quickly cool down the furnace through convection fans and coolers. The vacuum annealing furnace has strict sealing requirements, large capacity of the vacuum pump, and high requirements for equipment. It is generally used for annealing high-purity aluminum foil of electrolytic capacitors.